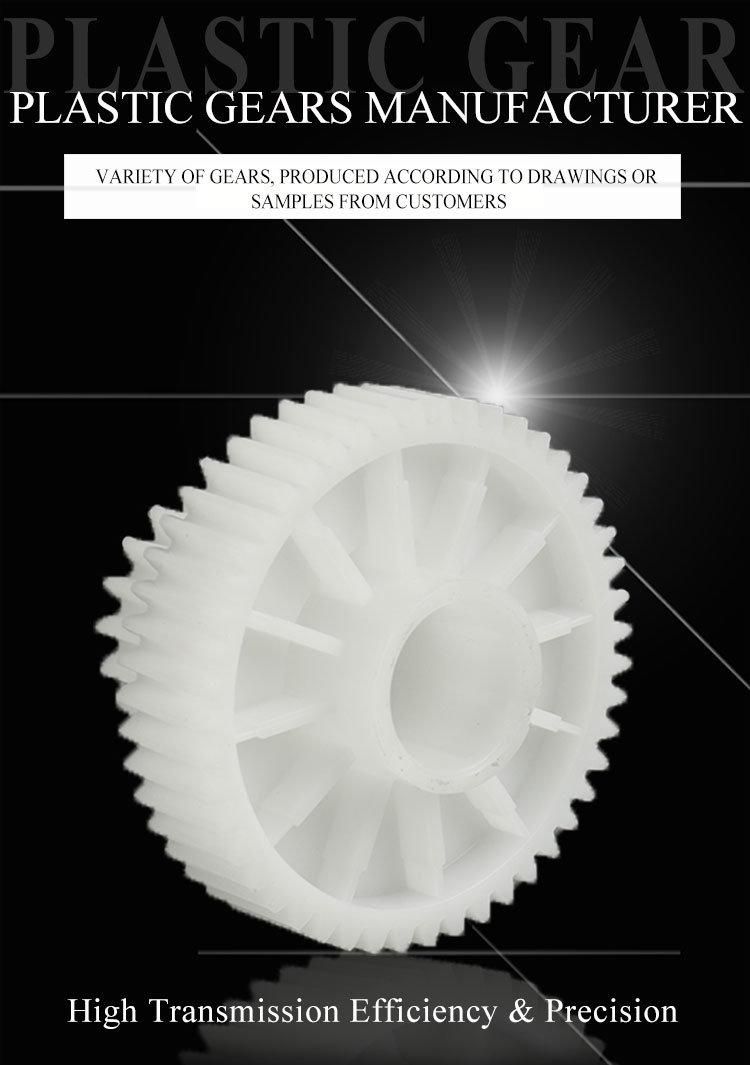

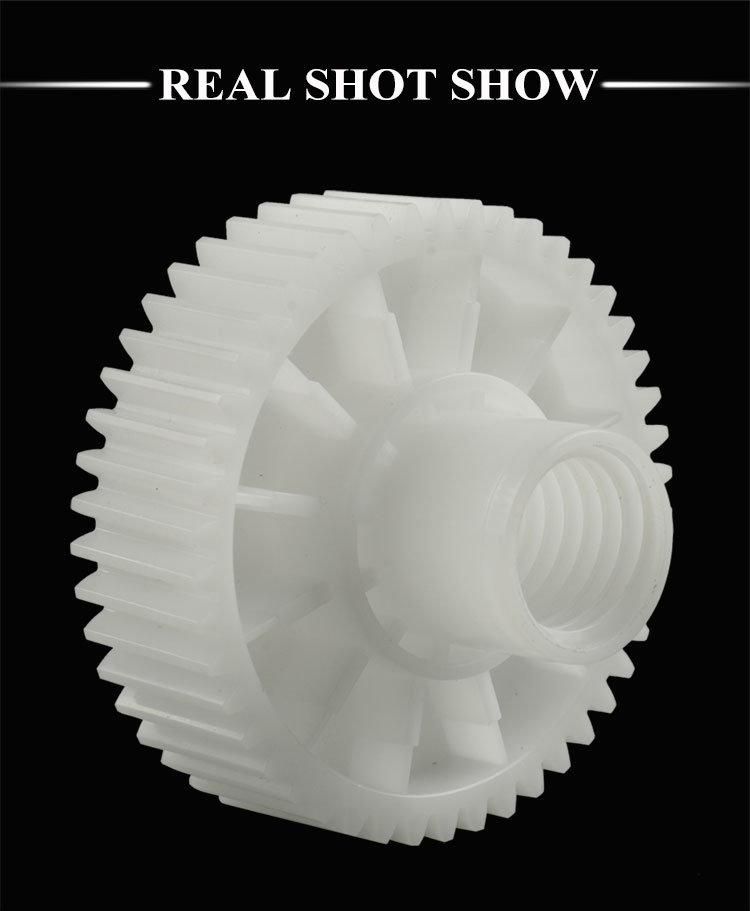

Custom Reduction Precision Transmission Involute Duplicate Injection Plastic Helical Gear

Dongguan Q&C Industrial Co., Ltd.- Application:Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car

- Hardness:Soft Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Injection Plastic Gear

- Toothed Portion Shape:Double Helical Gear

- Material:Plastic

Base Info

- Model NO.:QC-059

- Type:Circular Gear

- Moulding:Injection Plastic Gear

- Module:0.1 .02, 0.4, 0.5 1, 1.5, 2, 2.5, 3, 4, 5etc

- Teeth Shape:Helical Gear

- Transmission:Spiral Helical Gear

- Cog Wheel:Gear Wheel

- Gearbox:Gearbox Gear

- Reduction:Reduction Gear

- Moduluds:0.2, 0.3, 0.5, 1, 2, 3, 4etc

- Custom:Custom Gear

- Shaft:Shaft Gear

- Duplicate:Duplicate Gear

- Involute:Involute Gear

- Machine:Machine Gear

- Precision:Precision Gear

- Power Tool:Power Tool Gear

- Transport Package:PP Bags and Cartons

- Specification:20 teeth 30 teeth 40 teeth 60 teeth

- Trademark:Q&c

- Origin:Dongguan China

- HS Code:84834090

- Production Capacity:1000000,Month

Description

Basic Info.

Model NO. QC-059 Type Circular Gear Moulding Injection Plastic Gear Module 0.1 .02, 0.4, 0.5 1, 1.5, 2, 2.5, 3, 4, 5etc Teeth Shape Helical Gear Transmission Spiral Helical Gear Cog Wheel Gear Wheel Gearbox Gearbox Gear Reduction Reduction Gear Moduluds 0.2, 0.3, 0.5, 1, 2, 3, 4etc Custom Custom Gear Shaft Shaft Gear Duplicate Duplicate Gear Involute Involute Gear Machine Machine Gear Precision Precision Gear Power Tool Power Tool Gear Transport Package PP Bags and Cartons Specification 20 teeth 30 teeth 40 teeth 60 teeth Trademark Q&c Origin Dongguan China HS Code 84834090 Production Capacity 1000000/MonthProduct Description

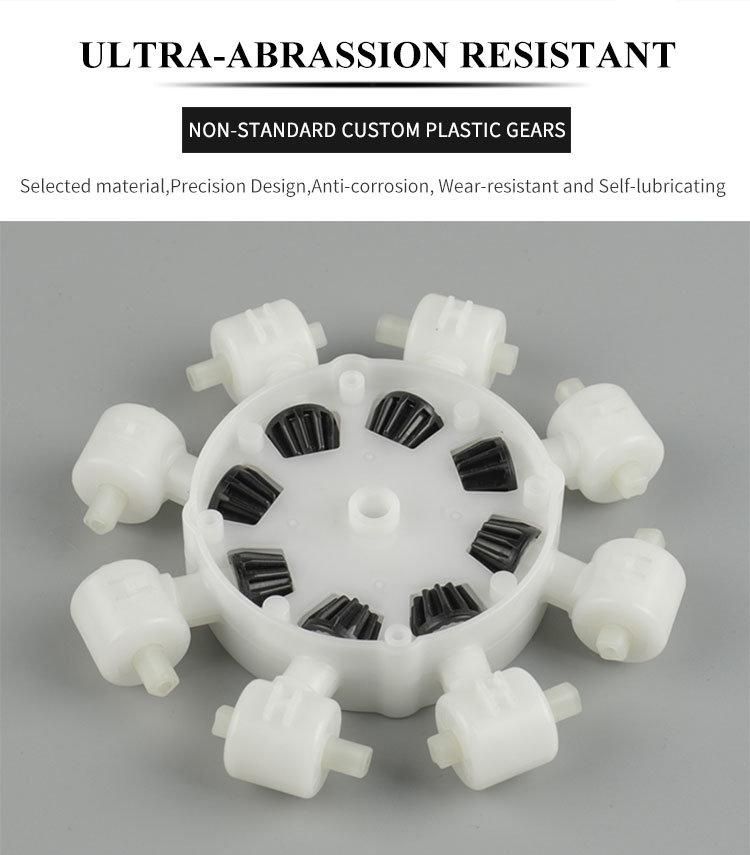

custom reduction precision transmission involute duplicate injection plastic helical gear| Item | Customized machined injection plastic gears |

| Craft Process | Plastic Injection or CNC machining |

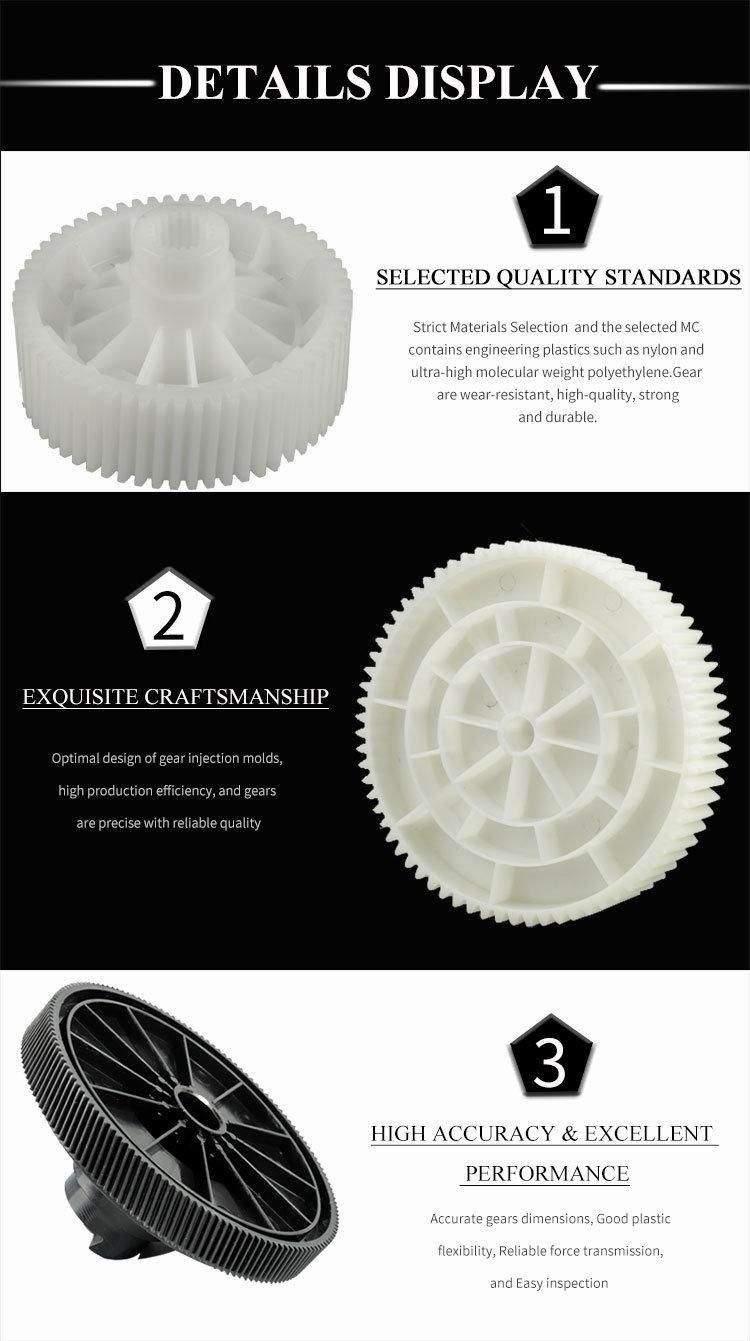

| Plastic Granules | UL, FDA, RoHS etc. |

| Quality Control | ISO9001 and ISO14001 |

| Molds Material | S316,H13,718,738,P20,H13,420SS |

| Mold Life | 300,000 shots or 1,000,000 shots or more |

| Mold Cavity | Single-cavity or two cavities or Multi-cavity |

| Material | Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc. |

| Molds cavity Hardness | 60 to 90 H.R.C |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. |

| Size Tolerance | ±0.05mm or more precise |

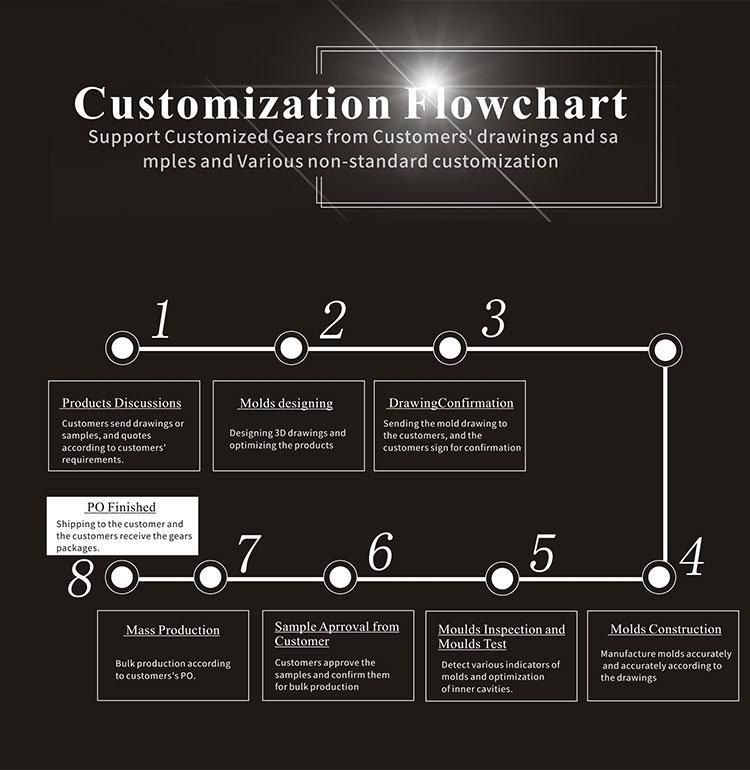

| Work Flow chart | Step1: Make tooling firstly and usual need 2~~3 weeks. Step2: Produce and confirm samples. Step3: One week for mass production usual. |

| Samples confirmation and approval | Free samples shipped for confirmation and shipping cost paid by customers |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer's requirements. |

| Delivery Time | Total takes 2~~4weeks usual |

| Payment Terms | PAYPAL, T/T, Western Union |

| Shipping | Usual FEDEX, UPS, DHL, TNT, EMS or base on customer's requirement. |

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.