High Quality Roller, Decoler, Coiler, Shear Cold Rolling Mill Parts Slitting Machine

Hebei Moran Environmental Protection Technology Corp.- Standard or Nonstandard:Nonstandard

- Feature:Flame-Retardant, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Wear-Resistant, Acid-Resistant, High Temperature-Resistance

- Application:Steel Rolling Equipment Spare Parts and Auxiliary

- Surface Treatment:Polishing

- Material:Alloy

- Transport Package:Carton or as Required

Base Info

- Model NO.:Model: cast steel roller, cast iron roller and for

- Specification:as clients′ requried

- Trademark:MoRan

- Origin:China

- HS Code:8455300000

- Production Capacity:50000 Pieces Per Year

Description

Basic Info.

Model NO. Model: cast steel roller, cast iron roller and for Specification as clients′ requried Trademark MoRan Origin China HS Code 8455300000 Production Capacity 50000 Pieces Per YearProduct Description

Hebei Moran Environmental Protection Technology.,Ltd, is one of leading cold rolling machine design and manufacture facility in China.Our products include steel and aluminum rolling mill, 2hi 4hi 6hi 8hi to 20 hi rolling mill machine, skin pass mill,

tension leveler, tension leveler and skin pass mix mil, caster, steel coating line, annealing furnace, grinder, and other related equipment and parts.

our machine has been exported to many country and enjoy a very good reputation among our users.

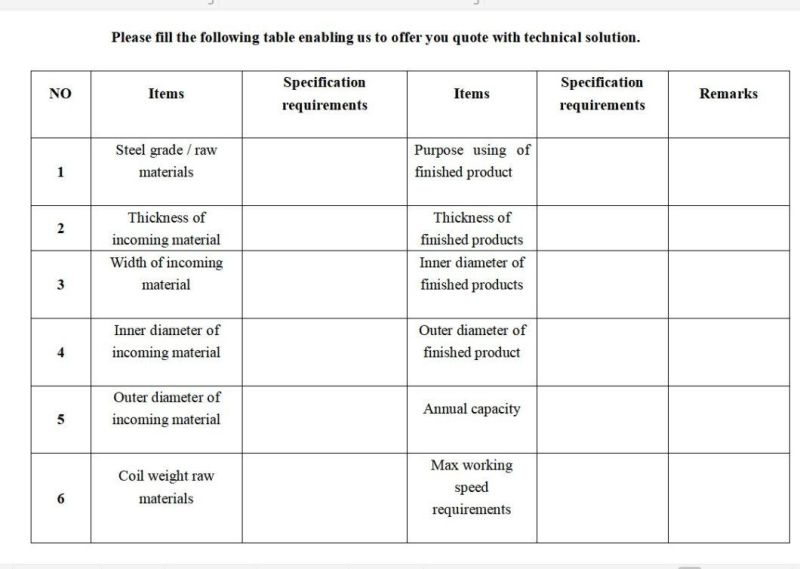

We also able customize for clients according to their demand and requirement. pls refer to the follow picture and contact us for more details.

Model: cast steel roller, cast iron roller and forging roll

Function: the roller is an important part of the rolling mill, the use of a pair or a group of rolling mill to produce the pressure of rolling mill. It is main device to the influence of static and dynamic load, wear and temperature changes during rolling.

Key point: during material under rolling process, the roller surface perfection and hardness will be direct effected finished production. Also because the rolling mill through roller distribute the presure on the input material to through material plastic force to reach demand thickness, then high quality and suitable strength will be the key of the rolling mill performance.

We offer:not limited by stander material hardness, highly function and performace customization roller and other related devices.