Yps Series Gearbox for Counterrotating Parallel Twin Screw Extruder

Jiangyin Gearbox Manufacturing Co., Ltd.- Application:Machinery, Marine, Agricultural Machinery, Plastic and Rubber Extrusion

- Function:Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction

- Layout:Helical

- Hardness:Hardened Tooth Surface

- Installation:Horizontal Type

- Step:Four-Step

Base Info

- Model NO.:YPS Series Gearbox

- Type:Cylindrical Gear Box

- Manufacturing Method:Rolling Gear

- Toothed Portion Shape:Spur Gear

- OEM/ODM Serivce:Available

- Warranty:12 Months

- Certificate:ISO9001-2008, SGS

- Transport Package:Packed in Wooden Case+Pallet

- Specification:76-110

- Trademark:JC, Duoling

- Origin:Jiangsu, China

- HS Code:8483409000

- Production Capacity:2000PCS,Month

Description

Basic Info.

Model NO. YPS Series Gearbox Type Cylindrical Gear Box Manufacturing Method Rolling Gear Toothed Portion Shape Spur Gear OEM/ODM Serivce Available Warranty 12 Months Certificate ISO9001-2008, SGS Transport Package Packed in Wooden Case+Pallet Specification 76-110 Trademark JC, Duoling Origin Jiangsu, China HS Code 8483409000 Production Capacity 2000PCS/MonthProduct Description

YPS Series Gearbox for Counterrotating Parallel Twin Screw Extruder

Company Information

Established in 1979, Jiangyin Gearbox Manufacturing Co., Ltd. is located in National High-tech Development Zone of Jiangyin, Jiangsu, China. With more than 38 years' experience in research and development of gear transmission products, the factory covers an area of 87,000 square meters. ISO9001certified in 1999, we have high qualified R&D engineer team and manufacturing talents as well as first-class processing and testing equipments.

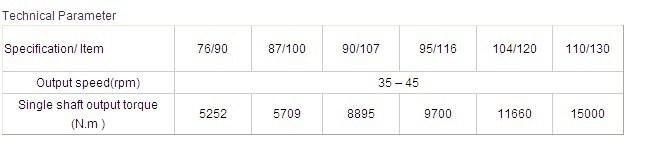

Specifications

high carry capacity, stable drive, low noise and high efficiency.YPS Series gearbox is a drive device designed to match with inverted parallel twin screw extruders. The main parts are manufactured by way of carburizing quenching hardening, and gear grinding. Its precision is up to Grade 6 (GB10095-88). Thrust bearing with over-specification is mounted on the front end of hollow output shaft to accommodate screw back pressure forces. The whole unit is small volume, high carry capacity, stable drive, low noise and high efficiency.