Manufacturer of Polyester Material Airslide Fabric

Century New Power (Tianjin) International Trade Co., Ltd.- Standard or Nonstandard:Nonstandard

- Application:Conveyer Equipment, Food Machinery, Mining Equipment, Agricultural Machinery

- Feature:Flame-Retardant

- Tensile Strength:Strong

- Material:Canvas

- Type:Pneumatic Conveyor

Base Info

- Thickness:4 - 6 mm

- Width:100 - 2800mm

- Weight:4kg,M2

- Structure:Woven Filter

- Warp Tensile Strength:6000n,Cm @ 2cm Length Sample

- Weft Tensile Strength:3000n,Cm @ 2cm Length Sample

- Working Temperature:-60 - 150 Degree

- Short-Time Working Temperature:200 Degree

- Air Pressure Loss:350PA @ 400m3,M2,H

- Warranty:2 Years From The Date of Load on Board

- Transport Package:Standard Export Packing: in Plastic Bag for Airsli

- Specification:customized

- Trademark:CNP

- Origin:China

- Production Capacity:50000 Meter,Month

Description

Basic Info.

Thickness 4 - 6 mm Width 100 - 2800mm Weight 4kg/M2 Structure Woven Filter Warp Tensile Strength 6000n/Cm @ 2cm Length Sample Weft Tensile Strength 3000n/Cm @ 2cm Length Sample Working Temperature -60 - 150 Degree Short-Time Working Temperature 200 Degree Air Pressure Loss 350PA @ 400m3/M2/H Warranty 2 Years From The Date of Load on Board Transport Package Standard Export Packing: in Plastic Bag for Airsli Specification customized Trademark CNP Origin China Production Capacity 50000 Meter/MonthProduct Description

INTRODUCTION

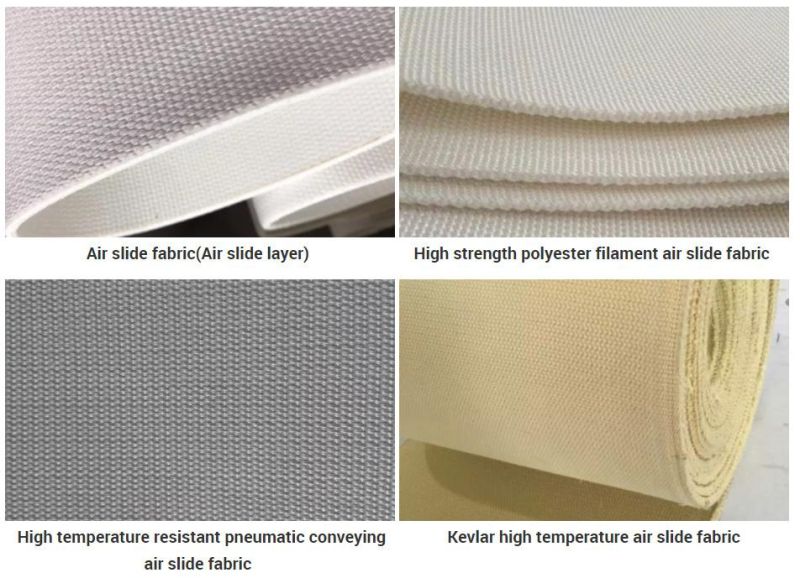

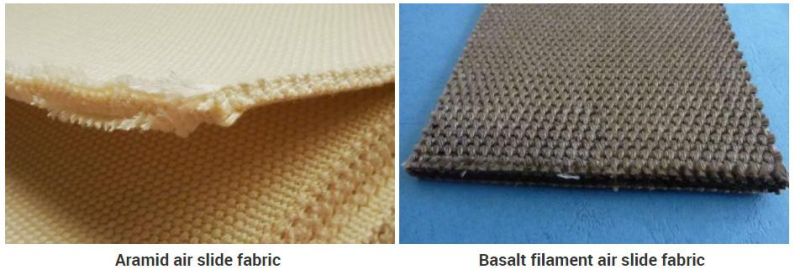

We provide Airslide belt for conveying bulk material by air gravity. The main use of Airslide belt is discharging, declining transportation or homogenizing the powder or small granular material in quiescent condition. Our airslide belt is named as Airslide fabric, Airslide membrane, Air slide cloth, Air slide canvas, Air permeable fabric, and Fluidization cloth, fluidising fabric, etc by our customer. We adopt 100% polyester for airslide fabric material.

Our fabrics can be used at temperatures between -60°C and +150°C. The airslide fabrics are made from polyester yarns.

We are also, however, able to weave fabrics to our customers' specific demands for air permeability and mechanical strength.

Advantages

No moisture absorptionNo cakingResistant to rotting and decompositionComplete unloading without residuesConsistent fluidization over the complete surfaceGood resistance to abrasionLow wear and therefore longer lifeLow shrinkage even when used under hot and humid conditions

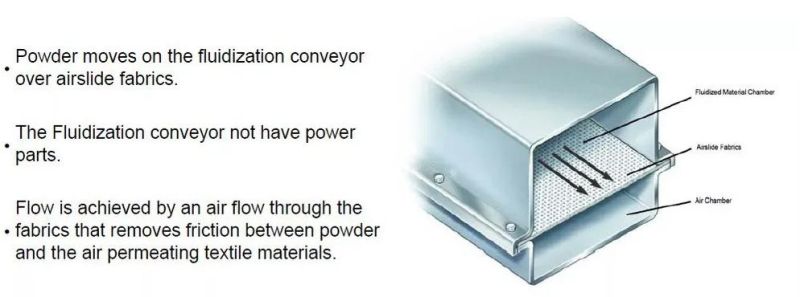

Working principle

In cement plant:

An Airslide belt is in the middle of a chute. Powder material will come into the chute above Airslide belt. Material will flow to the chute lower side as pneumatic blower down Airslide belt. That's why we say Airslide belt can move powder material because of the wind power. And then, the rest wind will go out from the top of the chute. Through the moving, no parts moved except powder material. So that it can spare more energy and maintain cost, etc.

In fluidization silo:

Our Airslide canvas is installed on the surface of the silo bottom. It is supplied for installation as aeration units on the sloped conical bottoms of bins and silos to aid in the withdrawal of dry relatively free-flowing material.

Each Airslide aeration unit package consists of 200mm open-type. Airslide conveyor units in lengths of 1.5 or 3m depend on the slope length of the conical storage area. Some spoke patterns are normally used with materials which have good fluidization characteristics. Others spoke patterns provide maximum aeration for difficult materials which can be fluidized.

In cement vessel's hold:

The sloped bottom of the cargo hold is covered with fluidizing panels. Our airslide fabric is on the surface of fluidizing panels. Rotary piston blowers supply the panels with oil-free compressed air and make the cement flow to the lowest point, where the discharge gate is installed.

Working occasions

In industry

Power Stations Filtered dust Flue ash, discharging flue ash Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz, Calcium hydroxide, lead monoxide, quicklime, acid crystals, Pure clay, phosphates, magnesite concentrate, finely ground fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer) Rubber compounds, sinter dust, catalysts Sodium sulfate Soap powder

In machinery:

Silos / Tanks Discharging systems Warehouse units Mixing equipment Homogenizing systems

Chute Bottoms Conveyor systems Ventilator systems Aeration systems

Vehicles

Silo truck discharging cones Railway wagon discharging cones Vessel aeration & discharging bottoms Container aeration & discharging bottoms

Powder Coating Machinery Bottoms for sinter basin

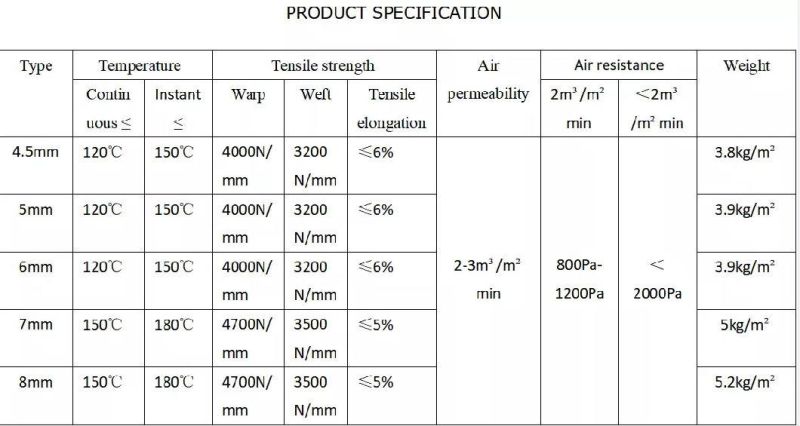

Specification data:

Raw Material =100% spun fiber polyester

Weight in average = 4000 g/m2 Thickness = 5mm

Mean Air Permeability = 400 m3/m2h @350H2O

Pressure: 2000pa for middle air resistance 4000pa for high air resistance

Breaking Strength- Warp=>6000 N/5cm X 20cm Breaking Strength- Weft= >3000 N/ 5cm X 20cm

Breaking Elongation - warp=<5% Breaking Elongation -weft=<5%

Max Width: 2800mm Operating Temperature < 150 deg.C

Recommended Maximum Continues <180 deg.C

Recommended Maximum Surge = 180 deg.C

Packaging & Shipping

We provide all kinds of standard export packing for cargo protection. The bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.

Our Services

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future

Company Information

CNP Co., Ltd. was founded in 2008, specializes in the field of air pollution control and bag filter, Including engineering design, planning, consulting, equipment research and development, manufacturing, sales, installation and commissioning, as well as production and services.

With national environmental design qualification and qualification certificate of foreign contracted projects, as well as certification of the IS09001, IS014001 and IS018001. Now we have become a much respected users-concerned PM2.5 dust control and industrial de-dusting solutions provider. We do contracting business of municipal solid waste incineration flue gas treatment system, electromechanical integration of environmental protection, total contracting capabilities of new technologies.

Since Five years ago, CNP has always regarded as our responsibility as to "Purify the atmosphere and benefit mankind", adhered to scientific and technological innovation and introduction, digestion and development. So far, we have developed more than 30 sets of series over 400 kinds of specifications of bag filter, successfully undertake and complete total contracting of a variety of types of large, medium-sized dust-removal, desulfurization project.

Achieve an annual output of dust filter area of one million square meters. Products are sold domestically and also exported to nearly 20 countries and regions, including Japan,Korea, Singapore , Australia, USA,Brazil, Russia, Portugal,India, Vietnam , Bangladesh. Products are widely used in metallurgy,boiler,waste incineration , nonferrous metals, building materials, food,light industry, chemical industry, machinery casting,electronics industries and so on.

Based on the high starting point, CNO Co., Ltd., with a positive and upward pioneering spirit, will further create brilliancy as to technological innovation, intellectual property rights and independent brand strategy.

Question:

Summary of Information Requested

It is important to us that we find out what is important to you, and offer the most effective solution for your specific dust collector needs.

To accomplish that, we will need to know as much of the following information from you as possible.

How much CFM will be needed for the Baghouse Dust Collector?

What type of material will you be collecting? and how much dust do you usually dispose of in a day?

What is the bulk density of the material?

Approximately what air velocity (FPM) are you looking for?

Do you have an Air-to-Cloth Ratio in mind?

What is the Air Temperature projected at the inlet duct?

Is the material explosive? If so, do you need a spark detection system, explosion vent, or sprinkler system?

How many pick-up points will there be?

What is the static pressure you are projecting for the system?

Are you wanting us to supply the Inlet Duct, Pick-Up Hoods, Installation, or Fan?

Do you want a Rotary Valve or Double Dump Valve, and is a screw conveyor required?

What are the height and size requirements, if applicable?

Do you have a specific filter bag material and construction that you are looking for?