Customized Bevel Gear Spur Gear with CNC Machining

Qingdao Xinghe Machinery Co., Ltd.- Application:Motor, Motorcycle, Industry

- Hardness:Hardened

- Gear Position:External Gear

- Manufacturing Method:Cast Gear

- Toothed Portion Shape:Bevel Wheel

- Material:Cast Iron

Base Info

- Model NO.:Customized Bevel Gear, Spur Gear

- Type:Bevel Gear

- Name:Customized Bevel Gear, Spur Gear with CNC Machinin

- Technology:CNC Machining Bevel,Spur Gear

- Teeth Number:58

- Tolerance:as Drawings

- Post-Processs:Hest Teatment

- POS-Process:Heat Treatment

- OEM and ODM:100% with Drawings.

- Packaging:Wooen, Carton, Pallet

- Delivery Time:30 Days

- Manipulate Way:Forced Manipulation

- Transport Package:Wooden Crate or by Customer′s Requirement

- Specification:Customized small rack and pinion gears

- Trademark:XH

- Origin:Qingdao China

- HS Code:84834090

- Production Capacity:10000tons , Year

Description

injection mould,4&5 axis machining

Qingdao Xinghe Machinery Co.,Ltd.

CNC machining:

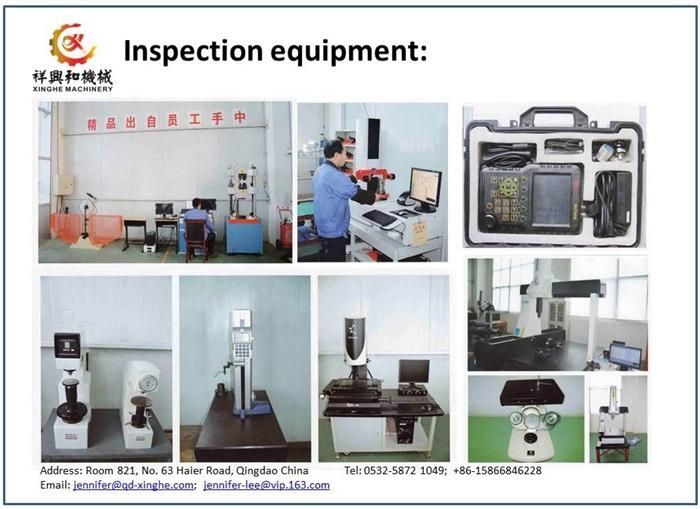

Inspection process:

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

Package:

Package:

1.) wooden, carton;

2.) pallet;

3.) as customers' requirement.

Our Services

1) Experience in casting for many years and served customers all around the world.

2) International advanced-level equipment such as CNC, numerical lathes, CMM.

3) OEM service, you demand is our pursued.

4) ISO quality control

FAQ- 1. How can I get thequotation?

Please send us information for quote: drawing, material, weight, quantity and request.

- 2. If we don't have drawing, can you make drawing for me?

Yes, we make the drawing of your sample and duplicate the sample.

- 3. When can I get thesample?

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

- 4. What is your main order time?

Order time: 35-40 days after the payment. The accurate time depends on your product.

- 5. What is yourpayment method?

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

- 6. Which kind of file format you can read?

PDF, ISGS, DWG, STEP, MAX..

- 7. If you export to our country before, can I get the information of your import customer in our country?

We can't offer you all the information of our customer because we have duty to protect our customers' privacy. But we can provide you some part of B/L.