Worm Gear Manufactures Gear Manufacturing Worm Shaft and Worm Gear

Baoding Jiangdashengye Trade Co., Ltd.- Application:Machinery, Agricultural Machinery, Car

- Function:Clutch, Change Drive Direction, Speed Changing, Speed Increase

- Layout:Coaxial

- Hardness:Soft Tooth Surface

- Installation:Horizontal Type

- Step:Stepless

Base Info

- Model NO.:BDJDM-002

- Type:Worm Gear Box

- Transport Package:Carton Box

- Specification:OD 8.65“

- Trademark:JDSY

- Origin:China

- HS Code:84869100

- Production Capacity:10000PC,Month

Description

About Us

Baoding Jiangdashengye machinery parts manufacturing was founded with the mission of supplying world class forging products at the best prices.

We have a strong engineering team to ensure the quality stability for our customers' projects. All our engineers have more than 10 years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

For any forging product, only if you supply a sample or operating requirements, our engineers will design the optimal forging process and subsequent testing or manufacturing process for your product.

We have been achieving our mission and delivering the most cost-effective, highest quality solutions to our customers.

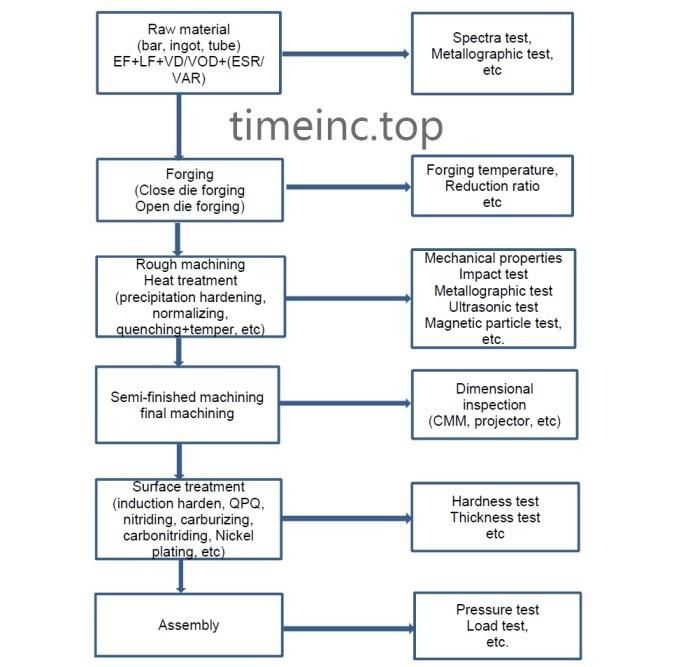

Our quality control begins from raw material, forging, heat treatment, semi-finished machining, final machining till assembly, each step is controlled strictly by our engineers, all of them have 10+ years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.

Contact Us

Jason

bdjdsy.en.made-in-china.com