Gear - Main Shaft Pinion Gear - 24 Teeth

Wenling Hengfeng Powder Metallurgy Co., Ltd.- Application:Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Sintered Gear

- Toothed Portion Shape:Spur Gear

- Material:Stainless Steel

Base Info

- Type:Circular Gear

- Transport Package:Carton or According to Client′s Request

- Specification:As Client′s Request

- Trademark:HF

- Origin:Zhejiang, China

- HS Code:84314990

- Production Capacity:1000000,Month

Description

Basic Info.

Type Circular Gear Transport Package Carton or According to Client′s Request Specification As Client′s Request Trademark HF Origin Zhejiang, China HS Code 84314990 Production Capacity 1000000/MonthProduct Description

Our Products Special Features,

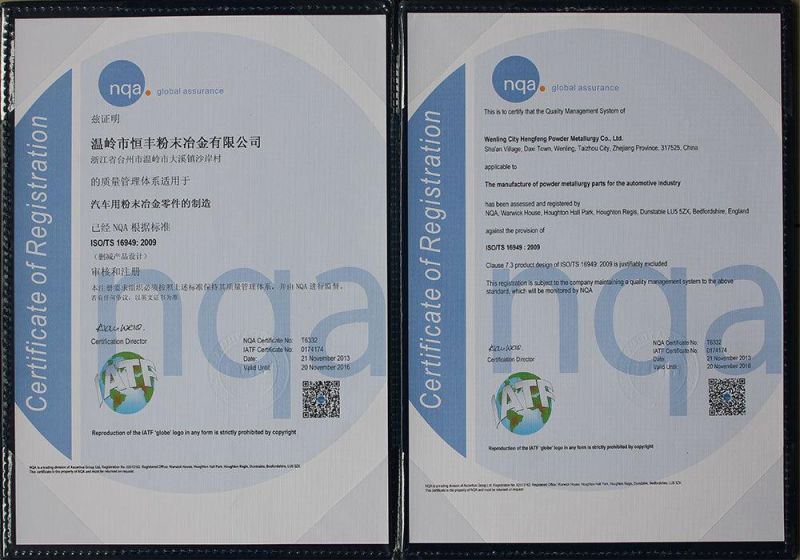

1) Our products passed TS16949 ISO-9001: 2000 quality management system verification

2) Material: Steel, copper, brass, aluminum, Titanium

3) Equipment: CNC lathe, CNC milling machine, CNC high-speed engraving machine, Common machines, laser engraving machines, metal injection machine

4) Precision machining capability:

5) Advanced workmanship, fitting tool, fixture, cutting tool

6) Parts can be supplied according to customers' drawings or samples.

7) 2D/3D drawings or samples are welcome!

8). Best quality, competitive price, shortest delivery time and good service.

| Place of origin: | Zhejiang, China |

| Brand Name: | Wenling Hengfeng Powder Metallurgy Co.,Ltd |

| Type: | Powder metallurgy sintering |

| Surface finish | e-coating, electroplating and black oxygen |

| Measuring method | 3D system, High-lubrication, high-density and high-strength |

| Inspection equipment | Torsion test, voltage feedback test, HRC density test, lifting test and salt spray resistant test and more |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron, stainless steel, copper, Alloy |

| Application: | Automotive parts, power tools, stainless steel, bushings, clutches and so many others |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgy, CNC Machining |

| Powder Metallurgy: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |