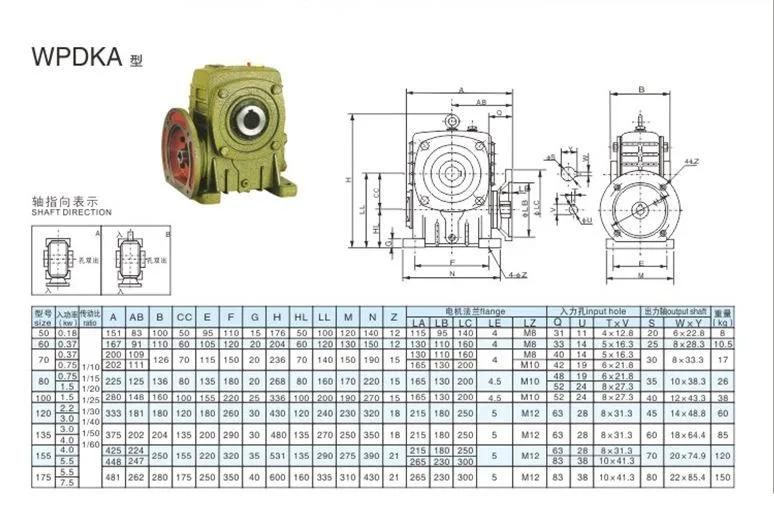

Eed Wpdka Series 60 Worm Gearbox Speed Reducer

Hangzhou Xingda Machinery Co., Ltd.- Application:Motor, Machinery, Agricultural Machinery

- Hardness:Hardened Tooth Surface

- Installation:Vertical Type

- Layout:Coaxial

- Gear Shape:Bevel Gear

- Step:Single-Step

Base Info

- Type:Worm and Wormwheel

- Manufacturing Method:Cast Gear

- Toothed Portion Shape:Spur Gear

- Input Speed:1400rpm

- Output Torque:1.8-2430n.M

- Rated Power:0.37kw

- Transport Package:According to The Customer Request

- Specification:ISO9000

- Trademark:OEM; EED

- Origin:China

- HS Code:8483409000

- Production Capacity:800-1500PCS ,Month

Description

Worm gear box

Place of Origin:Zhejiang, China (Mainland) Brand Name:EED

Gearing Arrangement:Worm Output Torque:1.8-2430N.M Rated Power:0.37KW

Input Speed:1400rpm Output Form:foot mounted, flange

Material:Alloy steel,Carbon steel, Stainless steel,cast ion ,Aluminum

Standard or Nonstandard:Customized Gear Heat treatment:Carburising, quenching, gear

Mount Position:Foot mounted, flange mounted Certification:CE, ROHS, ISO9000

Color:Customized Warranty:1 year Ratio:1/10.1/15,1/20,1/25,1/30,1/40,1/50,1/60

1. Widely used in turbines, shaft liners and axletrees, good resistance to wearing, with high precision in dimensions, lower noise, advanced centric running castings

2. Without vent and highly precision

3. The whole structure is compact and the weight is larger

1. Notice of installation

1.1 Thebase-plate must be plane and stoutness, and the base-plate must be screwed downand shockproof.

1.2 Theconnecting shaft of prime mover, reducer and operation device must be coaxialinstallation.

1.3 Thediameter tolerance zone of input and output shaft is H6, the holes of fittings(such as couplings, belt-pulley, sprocket wheel and so on) must properly matethe shaft, which prevents bearing from breakage because of over-loose mate.

1.4 Driverssuch as sprocket wheel and gear must be fitted close to bearings in order toreduce bending stress of hanging shaft. 1.5 Whiteassembling motor of WPD reducer, it is necessary that proper amount of butterapplies to the worm shaft input hole and keyway, avoiding assembling tootightly and rusting after using for a long time. 1.6 WhenOrdering or using all kinds of WPD type, if the motor weight is binger than thecommon, supporting set is required.

2. Notices of usage

2.1 Before using, please check carefully whether the reducer model, distance, ratio, input connecting method, output shaft structure, input and output shaftdirection and revolving direction accord with requirement.

2.2 According to the requirement of selecting lubricant oil in the productmanual, please fill proper category and brand lubricant. And then screw on thevent-plug; Unlock the small cone-plug of vent-plug. Only after doing these, reducer is already for starting up running. The proper brand and adequatelubricant oil is required, replacing oil in time conforming to the request ofproduct manual is also necessary, especially after using first 100 hours, it isrequired refilling new oil.

2.3 Whenabnormal circumstances occur, please stop and check reducer per solutions andreasons for faults of reducer (allowable highest oil temperature is 95, under this temperature limit, ifoil temperature no more goes up, please let reducer continue running)