OEM Customized Electric Power Steering Worm Gear with Low Noise

HK AA Industrial Co., Limited- Application:Marine, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:External Gear

- Manufacturing Method:Cut Gear

- Toothed Portion Shape:Double Helical Gear

- Material:Steel

Base Info

- Model NO.:worm gear

- Type:Worm And Wormwheel

- Descriptions:OEM Customized Electric Power Steering Worm Gear W

- Standard or Nonstandard:Nonstandard

- Model:Custom Made

- Micro Machining or Not:Micro Machining

- Process:CNC Machining Swing Clamp, CNC Milling Screw Clamp

- Services:OEM, ODM

- Package:Polybag+Carton

- Shipping:UPS, DHL, Air

- Delivery Time:10-25 Days for Samples;20-35 Days for Batch Goods

- Transport Package:Standard Export Carton, Inner: PP Bubble Bag

- Specification:ISO9001-2008 SGS IAF

- Trademark:HK AA

- Origin:Guangdong China

- HS Code:7318160000

- Production Capacity:20, 000,Month

Description

daily living equipment, electronic sports equipment, light industry products, sanitation machinery,

market/ hotel equipment supplies, artware etc.

Related products

Package

Shipping

1. FedEx/DHL/UPS/TNT for samples and small quantity parts, Door-to-Door;

2. By Air or by Sea for large quantity products,

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 10-25 days for samples; 20-35 days for batch goods.

Payment Terms,

1. Payment: T/T, PayPal; 50% deposits; 50% balance before shipping, special demand please consult with us

2. MOQ: 1pcs

3. Warranty : will provide you 100% qualified products, once fail please just reject or ask for refunding, it is our principle to do business providing clients qualified products

Company information

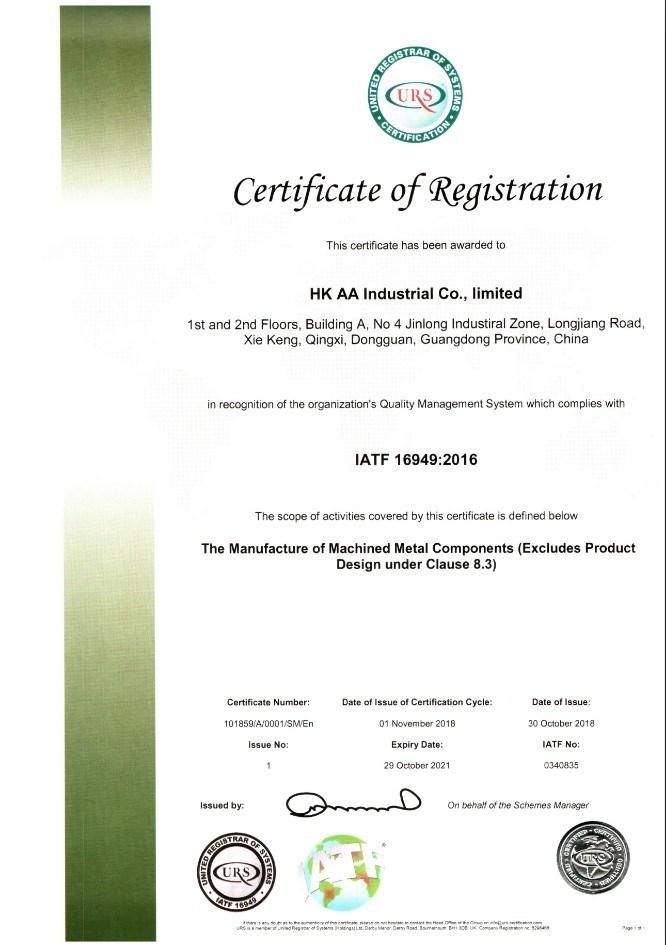

HK AA Industrial Co,. Limited, is located in NO 4 Building, Jinlong Industrial Zone Longjiang Road, Xiekeng, Qingxi, Dongguan, Guangdong province, China. HK AA was founded in 1998, covering an area of 11,000 square meters and 200 workers . 90% of our products are sold to overseas market such as USA, Canada, Germany, UK, Italy, Australia, Japan, South Korea etc. We are ISO 9001:2008, ISO13485 (medical)and TS16949(automotive) certified company. We will have AS9100 certificate(aerospace) In 2019.

Certification

FAQ

A1:we are ISO 9001-2008 certified firm. we have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2:What's the Advantage of Your Parts for Industry Products?

A2:Our advantage is the competitive prices, fast delivery and high quality. Our employees are responsible-oriented, friendly-oriented,and dilient-oriented. our Industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments include CNC milling machines, CNC turning machines, stamping machines,hobbing machines, automatic lathe machines, tapping machines, grinding machines, screw machines, cutting machines and so on.

Q4: What shipping ways our use?

Q5:Who are our main customers?

A5:HP, Samsung, Jabil Group,Lexmark,Flextronic Group.

Q6:What materials can you handle?

A6:Brass,bronze,copper,stainless steel, steel,aluminum,titanium And plastic.

Q7:How Long is the Delivery for Your Industrial Part?

A7:Generally speaking, it will take us 15 working days for machining parts and 25 working days for the for stamping parts products. But we will shorten our lead time according to customers' demands if we are able to.