-

Anti-Static Oil and Heat Resistant EPDM Rubber V Belt for Power Transmission

Click here to send us inquiry directlyApplicationCompany Introduction Hebei Heiyi Rubber Co.,LtdLocated in a historical and cultural city-Hebei Julu.The company now covers an area of 136 acres,buildingarea of 66000 square meters,more than 180 employees.Integrating R

-

Differential Planetary Gear Auto Parts for Planetary Carrier Gearbox

Basic Info. Model NO. 0145

-

Horse Equipment Gear Gearbox Transmission Gear Machinery Parts

Basic Info. Model NO. 0008

-

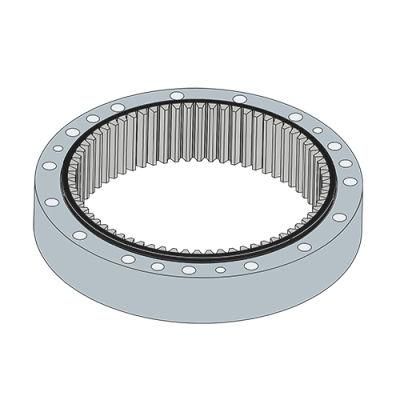

Cylindrical Gear Pair Inner Gear Shaping Tooth Gear Ring

Basic Info. Model NO. 0234

-

ND Brand Agricultural Gearbox for Agriculture Spike Drag Harrow Gear Box Pto

Overview Product DescriptionCompany ProfileIn 2010, Hangzhou Hengnie Machinery Co.,ltd was established by Ms. Iris and her two partners(Mr. Tian and Mr. Yang) in Tongxiang city(Zhejiang province, China), all three Founders are engineers who have more than averaged 30 years of expe

-

ND Brand Agricultural Gearbox for Agriculture Chisel Plow Gear Box Pto

Overview Product DescriptionCompany ProfileIn 2010, Hangzhou Hengnie Machinery Co.,ltd was established by Ms. Iris and her two partners(Mr. Tian and Mr. Yang) in Tongxiang city(Zhejiang province, China), all three Founders are engineers who have more than averaged 30 years of expe

-

High Quality SWC Industrial Flexible Steel Propeller Universal Joint Cardan Shaft Coupling

Product NameDensen customized SWC-BF Type universal coupling shaft coupling,universal couplings jointDN mm160~640mmAxis Angle25/15°Rated Torque16~1250 N·mFatigue torque8~630N·mMaterial35CrMoApplicationWidely used in metallurgy, mining, engineering and other fields.Product showCompa

-

42cr/45# Transmission Parts Coupled Drive Shaft Universal Coupling/Cardan Propeller Shaft Coupling

Product NameDensen customized SWC-BF Type universal coupling shaft coupling,universal couplings jointDN mm160~640mmAxis Angle25/15°Rated Torque16~1250 N·mFatigue torque8~630N·mMaterial35CrMoApplicationWidely used in metallurgy, mining, engineering and other fields.Product showCompa