Factory Supply High Precision Powder Metallurgy Small Spur Gear

Shijiazhuang Jingshi New Material Science and Technology Co., Ltd.- Application:Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

- Hardness:Hardened Tooth Surface

- Gear Position:Internal Gear

- Manufacturing Method:Sintered Gear

- Toothed Portion Shape:Spur Gear

- Material:Cast Iron

Base Info

- Type:Circular Gear

- Density:6.4-7.4 g,cm3

- Transport Package:PE Bag, Bubble Bag, Carton, Pallet

- Trademark:HLXCL

- Origin:China

- Production Capacity:5000000pieces,Year

Description

Basic Info.

Type Circular Gear Density 6.4-7.4 g/cm3 Transport Package PE Bag, Bubble Bag, Carton, Pallet Trademark HLXCL Origin China Production Capacity 5000000pieces/YearProduct Description

Custom Powder Metal Gear

| Product Name | High precision gear manufacturers by powder metallurgy |

| Material | Iron powder, alloy powder,precious metal powder |

| Technology | Sintering - Powder Metallurgy |

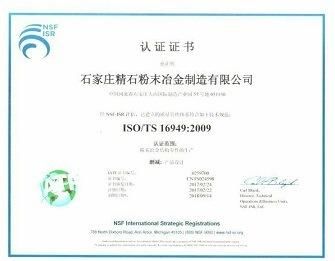

| Certificate | ISO9001/TS16949 |

| Surface Treatment | High frequency quenching, oil impregnation,CNC,vacuum cleaning,polishing, |

| Apperance | No crumbling, cracks, exfoliation, voids, metal pitting and other defects |

| Process Flow | Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing |

| Application | Motorcycle parts, auto parts, Power Tools parts, Motor parts, electric Bicycle, |

Why Powdered metals?

Significant cost savings.Create complex or unique shapes.

No or minimal waste during production.

High quality finished products.

Strength of materials

Production process of powder metallurgy

Powder mixing - Forming - Sintering - Oil impregnation - Sizing -Ultrasonic cleaning - Steam oxidation - Oil impregnation - Final inspection - Packing

Company Profile

JINGSHI established in 2007

Manufacturer & Exporter

Exacting in producing powder metallurgy gears and parts

Passed ISO/TS16949 Quality Certificate

Advanced Equipment

Numbers senior R & D engineers and Skilled operators

Precise Examination Instruments.

Strict Quality Control

With the "More diversity, More superior, More professional " business purposes, we are committed to establish long-term friendship and win-win relationship with domestic and international customers to create a bright future .

Certification

Please Send us your 2D or 3D drawings to start our cooperation!