Densen Customized Fan Coupling, Fan Shaft Coupling, Shaft Coupling Machined Shaft Machining

Shenyang New Densen Casting and Forging Co., Ltd.- Standard Or Nonstandard:Standard

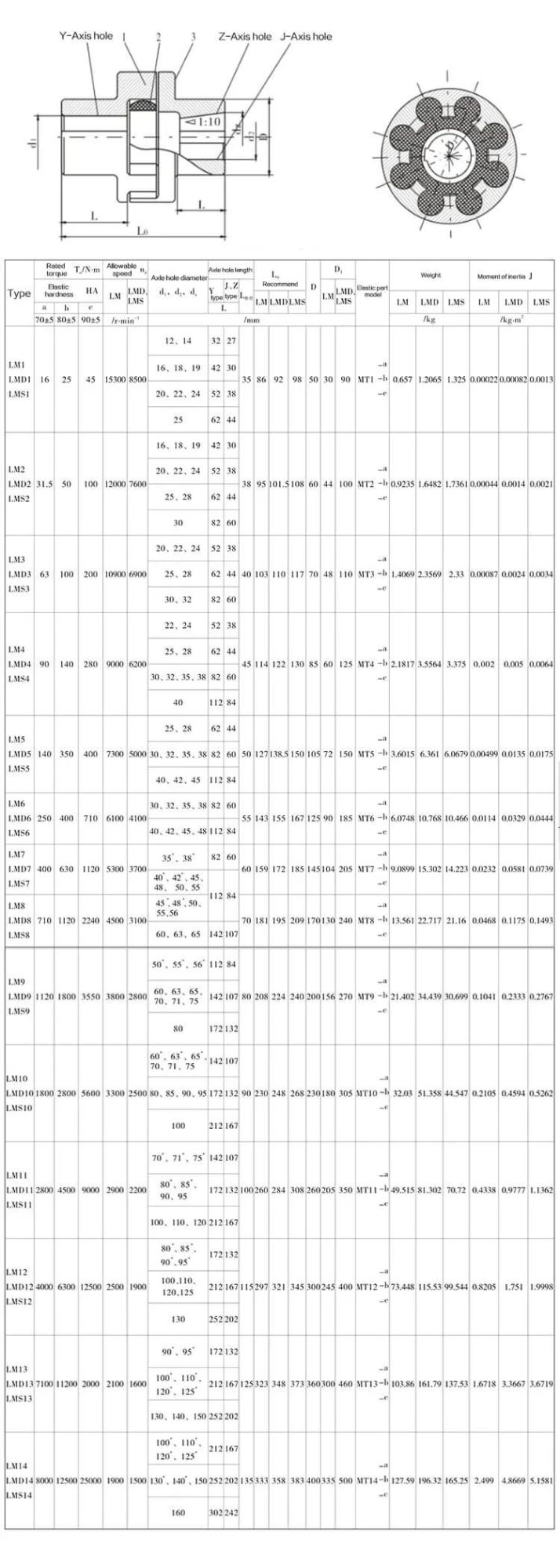

- Torque:25~250000nm,Customized

- Bore Diameter:12~160mm,Customized

- Speed:1500~15300rpm,Customized

- Structure:Flexible

- Material:Steel

Base Info

- Model NO.:Jaw,Spider coupling

- Type:Jaw,Spider Coupling

- Color:Customized

- MOQ:5 PCS

- Application:Industrial Equipment

- Surface Treatment:Blackening,Printing,Nitridation

- Certification:ISO9001

- Bore Size of Hubs:Customized

- Transport Package:Standard Export Wooden Box

- Specification:Customized

- Trademark:OEM

- Origin:China

- Production Capacity:1000 Piece,Pieces Per Month

Description

Product show

Company Information

Equipment

Application Case

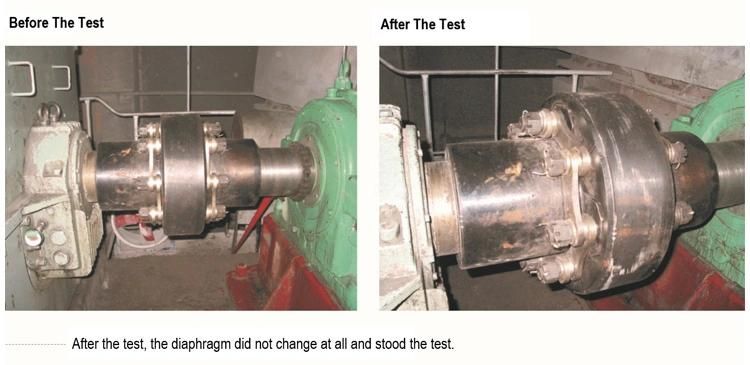

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to Daqing Oilfield Thermal Power Plant

According to the requirements of Daqing Electric Power Corporation, Daqing Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by Shenyang Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than one year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us