Sprocket Rim for Excavators Undercarriage Parts PC220-1-3-5 Segment

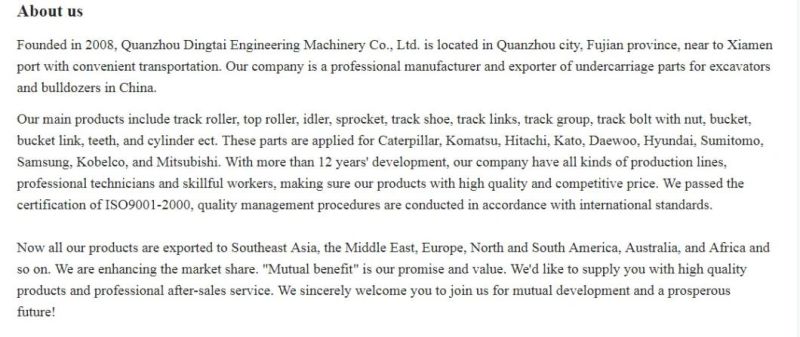

QUANZHOU DINGTAI ENGINEERING MACHINERY CO., LTD.- Standard Or Nonstandard:Standard

- Application:Excavator & Bulldozer Spare Parts

- Hardness:Hardened Tooth Surface

- Manufacturing Method:Forging Casting

- Toothed Portion Shape:Curved Gear

- Material:Cast Steel

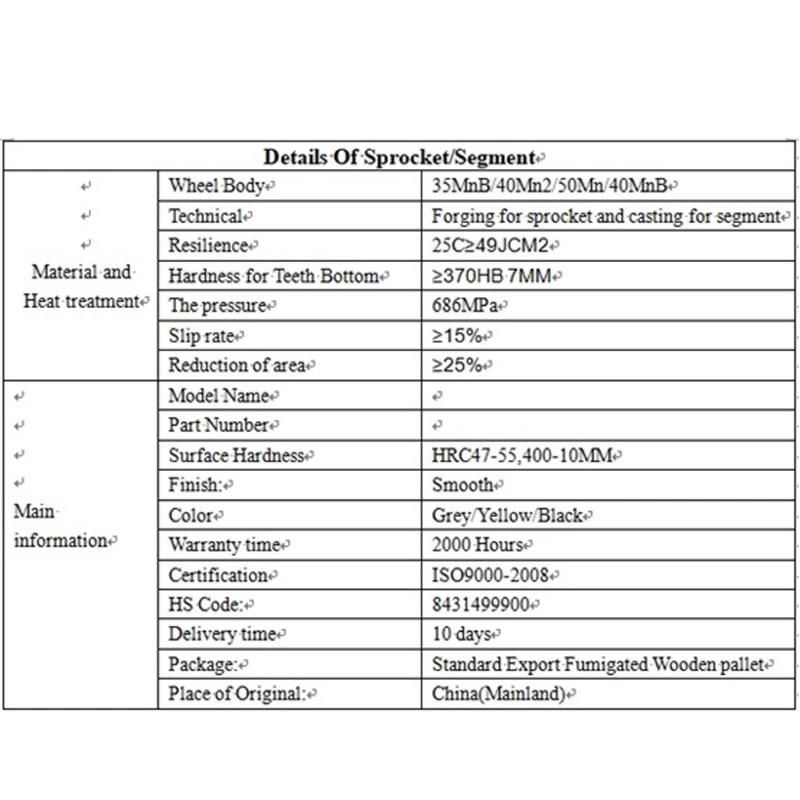

Base Info

- Model NO.:PC220-1-3-5

- Product Name:Sprocket Wheel

- Color:as Customer′s Requires

- Finish:Smooth

- MOQ:2 Pieces

- Warranty:2000 Hours

- Port of Shipment:Xiamen

- Time of Delivery:Within 15 Days After Contract Established

- Transport Package:Wooden Pallet

- Specification:PC220-1-3-5

- Trademark:Dingtai

- Origin:Quanzhou, China

- HS Code:84314999

- Production Capacity:50000 Pieces ,Month

Description

Basic Info.

Model NO. PC220-1-3-5 Product Name Sprocket Wheel Color as Customer′s Requires Finish Smooth MOQ 2 Pieces Warranty 2000 Hours Port of Shipment Xiamen Time of Delivery Within 15 Days After Contract Established Transport Package Wooden Pallet Specification PC220-1-3-5 Trademark Dingtai Origin Quanzhou, China HS Code 84314999 Production Capacity 50000 Pieces /MonthProduct Description

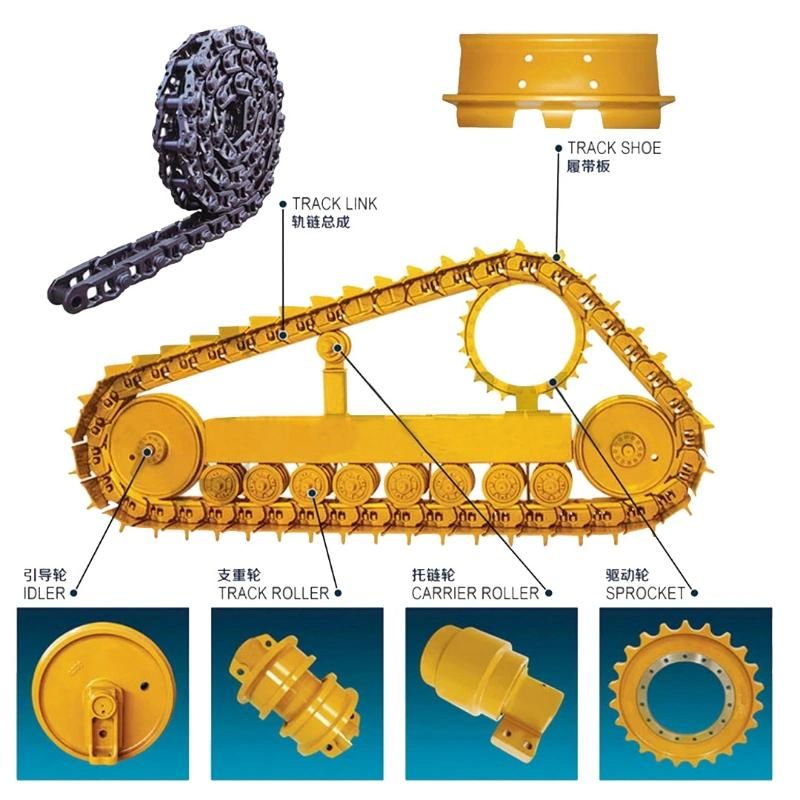

Sprocket For Excavators undercarriage parts PC220-1-3-5Sprocket

Product Details

Feature:

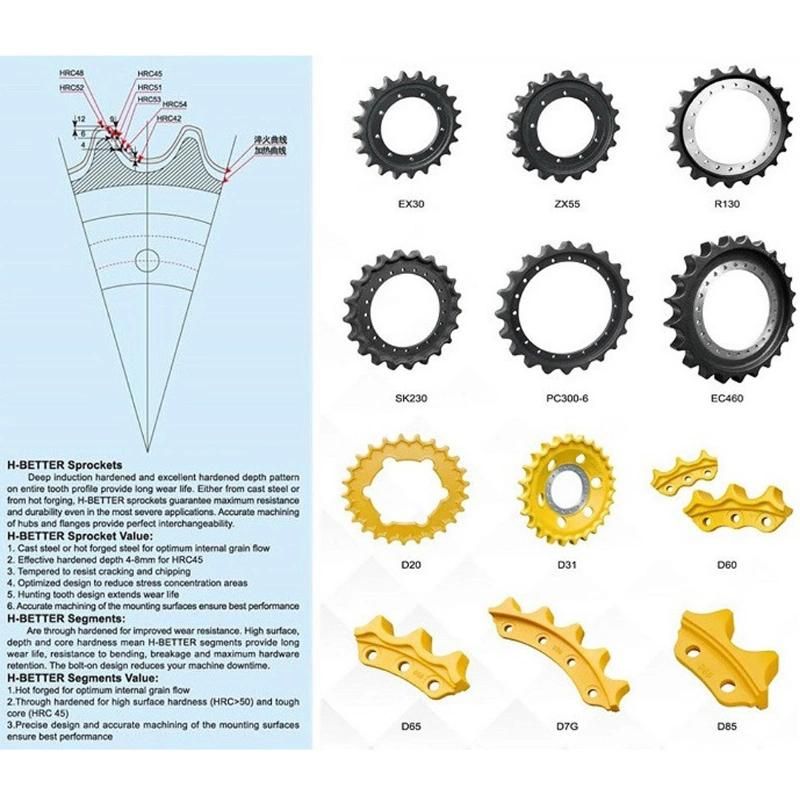

Deep induction hardened and excellent hardened depth pattern on entire teeth profile provide long wear life.Either from cast steel or from hot forging, DINGTAI sprockets guarantee maximum resistance and durability even in the most severe applications.

Accurate machining of hubs and flanges provide perfect interchange ablity.

1)We are able to assure the part has excellent wear resistance even in the most severe working conditions

2)We are using advance machining centre,horizontal and vertical CNC machining to execute processes such as machining, drilling, threading and milling to ensure the qulity and precision of each component to ensure the accuracy of assembly dimensions. This is to maximize the life span of each component and minimize production cost per hour.

Advantages:

1). Quality guarantee2). Technical support

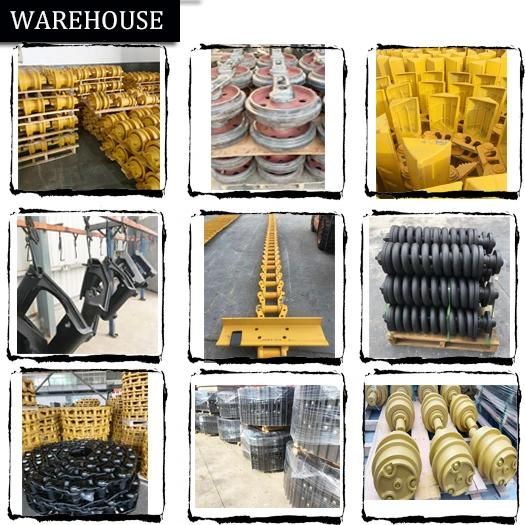

3). Gather different parts into one container

We provide below related product

Sprocket For Excavators undercarriage parts PC220-1-3-5